IT'S taken almost half a million man hours to bring the construction of the new cable stay bridge across the River Wear at Sunderland to its half way completion point.

Belfast-based Farrans Construction is delivering this unique £117 million development as part of a joint venture with the Belgian steel fabrication company Victor Buyck.

The project also involves the significant input of other locally-based companies with an involvement in the construction and engineering sectors, chief among them Ballymena-based Moore Concrete Products Ltd.

The bridge, when completed, will be 336m long and will facilitate two lanes of traffic on either carriageway along with a three metres wide shared cycleway – footway on each side of the bridge.

Also included in the development will be 2.8km of new carriageway. It is at the heart of the Sunderland Strategic Transport Corridor. The focal point of the new bridge will be a 105m high steel pylon, from which will radiate out the cable stays supporting the bridge deck.

“This is a landmark project for the Sunderland area, one which will drive forward the strategic development of the city, from both a regeneration and future investment perspective,” according to Farrans’ Stephen McCaffrey, the project director.

“This is the most challenging bridge project we've ever undertaken and the first highways bridge with a cable stay design. Its complexity has required a tremendous planning input, involving ourselves and those other international companies working on the development of the bridge.

“Site works commenced in May of last year. The new structure will be commissioned in advance of its planned opening in spring of 2018.

“And when fully operational, it will cater for 27,000 vehicles per day.”

The bridge project has already been seven years in development, with the office bearers of Sunderland City Council making no secret of its strategic importance for the region as a whole

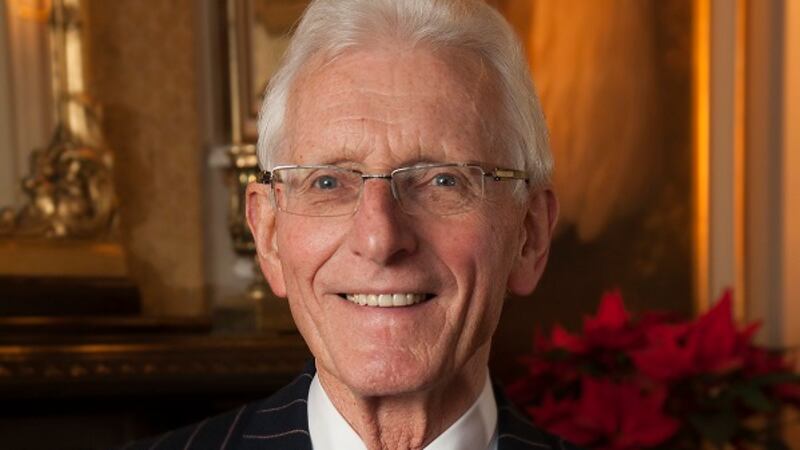

Cllr Paul Watson, leader of Sunderland City Council, said: “The people of Sunderland have waited a long time for this, so it’s wonderful to finally see the bridge unfolding and our ambitions become a reality. It’s a complex project, but we have the right skills and expertise in place to ensure it is delivered on time and to the highest standards.

“The new crossing is going to attract investment into Sunderland, help to regenerate key areas along the river, reduce journey times for motorists, and inject a great sense of pride into the community. There are no doubts in my mind that it will have a profound impact on the future of this great city.”

The physical scale of the project is immense.Its completion will require 3,000t of steel, 4250t of pre-cast concrete decking elements and 100km of cabling. Its development has also entailed the input of an international design team.

Pre-cast business Moore Concrete is manufacturing all of the pre-cast concrete deck units for the new bridge. These involve 38 different designs comprising a total of 850 units ranging in weight from 5 to 15 tonnes.

“We have enjoyed a long working relationship with the team at Moore’s,” Stephen explained.

Moore’s sales manager Richard Whiteside confirmed that the new bridge is the largest structure which the company has ever supplied components for.

“Over the past number of years, we have invested heavily in the manufacturing facilities and skills’ base to allow us commit to projects of this scale. And, obviously, we want to build on this for the future,” he said.

“The Sunderland project has required the co-ordinated input of our own engineering, design and manufacturing teams so as to ensure the precast units meet all the required quality standards and that delivery times are consistently achieved.”

The past few days have been marked by the first phase of the bridge decking being launched across the river.

“This represents a critical stage in the development of the overall project,” said Stephen McCaffrey.

“The pylon, which will be pre-fabricated in Belgium, should arrive with us on a specialised barge in early 2017. Its erection will follow almost immediately thereafter, which should allow us complete the bridge and adjacent road carriageways by early 2018.

“I can confirm that the project is on schedule to be completed on time. This is good news for the people of Sunderland and for all the companies involved in the development of what is a truly iconic bridge structure.”